MEMOSTAP Staple

Product description

The MEMOSTAP staples have shape memory and are manufactured at the facilities of SARL CHOC, rue Louis Lépine, Albasud 3, 82000 Montauban, France.

The MEMOSTAP staples are manufactured from ASTM F 2063 - 00 standard Nitinol. All materials are obtained from ISO 9001 certified suppliers, who provide for each titanium delivery a material conformity certificate with a physicochemical analysis.

The MEMOSTAP staples are produced in accordance with our manufacturing" procedures: a manufacturing order is issued by the Production Manager. For each manufacturing order, the Production Manager assigns a four digit batch number. The manufacturing order details all the operations to be carried out on the products. At each stage, various dimensional verifications are carried out by the manufacturing operators and by the Production Manager. All inspection forms are kept with the manufacturing order.

MEMOSTAP staples have shape memory and are super elastic.

Dimensional characteristics

PL101300 (13mm) / PL101400 (14mm) / PL101600 (16mm)

PL101700 (17mm) / PL101315 (13/15mm) / PL101416 (14/16mm)

PL101517 (15/17mm) / PL101618 (16/18mm) / PL101719 (17/19mm)

MEMOSTAP STAPLE

PL101300 (13mm) / PL101400 (14mm) / PL101600 (16mm)

PL101700 (17mm) / PL101315 (13/15mm) / PL101416 (14/16mm)

PL101517 (15/17mm) / PL101618 (16/18mm) / PL101719 (17/19mm)

SURGICAL TECHNIQUE

The staples, manufactured from Nitinol (not to be used with patients allergic to Nickel), are used in shortening osteotomy procedures.

On opening the peel-off blister, put to one side the traceability stickers (1 for order renewal, 4 for the patient file)

- Drill a hole with the 2 mm diameter drill bit (PLC0103) perpendicularly to the phalanx.

- Proceed with shortening

- Realign and maintain the phalanx in position

- Place the drill guide solid pin (PLC0101) in the previously drilled hole, and adjust the centre distance to 10 mm

- Drill a second hole using the 2 mm drill bit (PLC0103)

- Using a depth gauge, choose the corresponding staple size

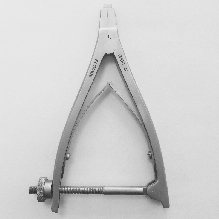

- Place the staple using the fixation forceps (PLC0102)

- Insert the staple using the staple punch (14.33.53).

Do not use the staple if its package is damaged.

To ensure staple traceability, they are individually packed in EN ISO 11607-1 standard double blisters. The first contains the staple and a sterilisation indicator label. The second blister contains the first blister and five traceability stickers with the staple reference, description and batch number.

The packed staples are then sent to ISOTRON France (MIN des Arnavaux- 13014 MARSEILLE) for sterilisation by gamma radiation according to the ISO 11137-02, ISO 11737-1, ISO 11737-2, EN 552, EN 556 standards and dose mapping. After sterilisation, ISOTRON returns the batch of sterilised products with a certificate of sterilisation by gamma radiation.

The staples in the packaging are then labelled. The label includes the description, the reference, the production batch number, the method of sterilisation, the expiry date, the "single use" and "read instructions before use" symbols, the manufacturer's name and address and the CE 1014 markings.

The staples are packed in boxes identically labelled as above, stretch-wrapped and stored in closed cupboards, away from direct light.

Storage conditions: no special conditions.